TUBETEX GAS

THE SEAMLESS WOVEN TEXTILE LINER FOR GAS PIPES

NordiTube has over 30 years of experience in the rehabilitation of gas pipes with TUBETEX GAS.

Three decades of experience and many hundreds of kilometers of rehabilitated pipes underline the maturity of TUBETEX GAS.

PERFECT SOLUTION FOR GAS MAINS

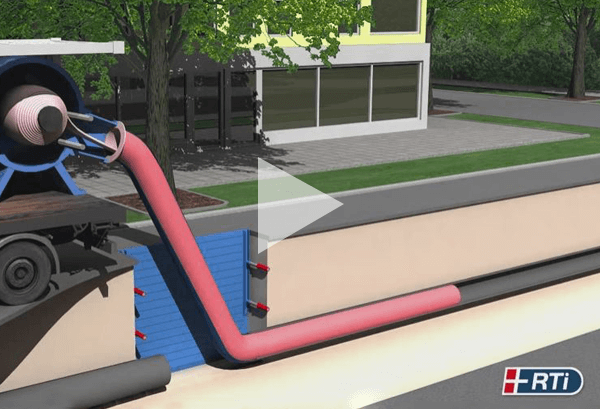

TUBETEX GAS is a CIPP liner for trenchless pipe rehabilitation especially developed for gas mains.

GENERAL DESCRIPTION

TUBETEX GAS can be produced in a seamless production up to 500 – 600 m. The limitation occurs only due to the capacity of spools. Therefore, there is no seam in the woven fabric which means an even wall thickness over the circumference. This is an important feature for Class C linings which relies on bonding, especially for gas pipes.

TUBETEX GAS liner consists of a woven textile liner, having on one side an hytrel coating which is the new inner pipe surface. Using a special epoxy resin system, the uncoated face of TUBETEX GAS is entirely bonded to host pipe.

TUBETEX GAS is an adhesive-backed hose renovation technique. It is an interactive system relying on the bonding with the host pipe and is classified as “Class C” according to ISO 11295.

THE BENEFITS AT A GLANCE

- High efficiency, less costs due to perfectly harmonized materials and optimized installation methods

- Remains tight in case of stress cracks and displacement

- Very good hole and gap span

- Good performance in bends

- Pressure classification up to 30 bar according to DVGW GW 327 possible

- Simple and inexpensive connection technology

- Long installation lengths through good processing time

- Short installation time through fas curing (steam)

- Thin and even wallthickness

- Stops internal corrosion

- Seals leaking joints and corrosion pits, cracks,…

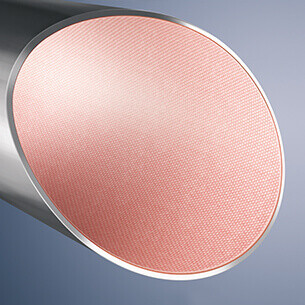

HYTREL TM

HYTREL TM is a type of TPE and provides a low permeability to gases and can therefore be used perfectly to reline gas pipes.

- excellent flexibility at room and low temperature

- excellent flex crack resistance

- excellent resistance to stress relaxation and creep

- high resilience

TUBETEX Gas at a glance

| TUBETEX GAS | |

|---|---|

| Application area | PRESSURE • Gas |

| Diameter | 150 - 1000 mm |

| Material | Seamless woven fabric |

| Coating | TPC (Thermoplastic Copolyester) |

| Resin | Adhesive epoxy resin |

| Classification according to ISO 11295 | C |

Approved systems in combination with resins from NordiTube available