ONSITE INTRODUCES NORDIPIPE IN UK FIRST

OnSite has used the NORDIPIPE™ relining system for the first time in the UK for the Loddon rising sewer main rehabilitation.

Anglian Water engaged wastewater management contractors OnSite to assess and provide a rehabilitation solution for a 713 m section of 300 mm diameter rising main between a pumping station and collection point that had experienced multiple bursts.

UK – January 2018

INITIAL SITUATION

There were a number of challenges that needed to be overcome.

One major complication for the completion of the proposed rehabilitation was that part of the route of the rising main ran through a site of special scientific interest (SSSI). This meant that an open cut solution not even be considered.

Furthermore, access to the pipeline was also difficult. A site meeting was arranged with the client Anglian Water, Onsite and Claret Civil Engineering (the civils contractor) to discuss available options and to target the problematic areas of the route.

As part of the discussions it was suggested that as the existing host pipe had failed on multiple occasions any solution needed to provide a standalone result, one that did not require the host pipe to be part of the final structure. Also, the lining had to be designed for an internal operating pressure of no more than 5 bar.

PROVIDING THE RIGHT SOLUTION – NORDIPIPETM

It was of course vitally important that the right liner material was used on such a sensitive project, so OnSite decided to introduce, for the first time in the UK, the NORDIPIPE™ system from Austriabased NordiTube Technologies SE.

The unique performance characteristics of NORDIPIPE™ , namely its flexibility and quick installation, make it possible to rehabilitate many kinds of pipes (steel, ductile and cast iron, asbestos cement, concrete, PVC, and PE). Moreover, it can be used to reline both partially and fully deteriorated pipes and often pipes with bends and deflections. Furthermore, it is a strong liner and therefore able to withstand not only the internal pressure, but also external pressure resulting from hydrostatic, soil and live load situations.

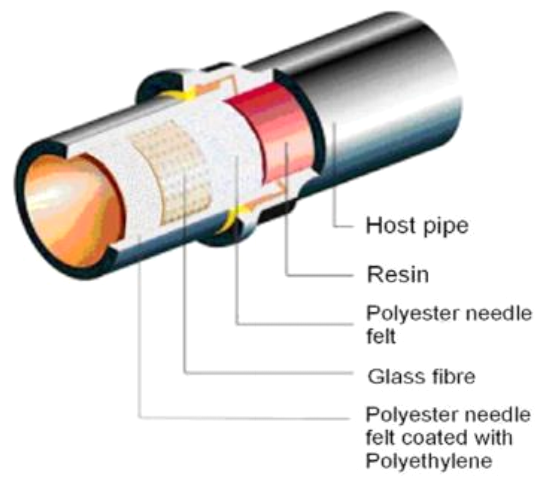

The 300 mm diameter, 6 mm wall thickness liner for Loddon consisted of a combination of a coated felt, two glass-fibre layers and an additional layer of felt. The glass-fibre layers in the liner have excellent characteristics when in tension and therefore this makes the NORDIPIPE™ a very strong, but flexible liner. It has its own intrinsic strength and stiffness and therefore does not rely on the host pipe for structural support, though it needs to be in close contact with the host pipe to maximise the final lined pipe’s cross-section, and to enable the ends to be sealed off properly.

INSTALLATION

Before the liner is impregnated, the correct liner length needs to be determined. The line length has to be measured and transmitted from the site to the impregnation facility including any turnback required to get to the face of the host pipe.

At the impregnation facility, the liner has to be sealed off at both ends. This enables a vacuum to be applied at the end where the resin is to be poured into the liner. The right amount of resin and hardener is then mixed and poured into the liner.

The resin plug is then allowed to run inside the liner. The liner is then pinched between the roll bars of the impregnation bed and the liner is slowly drawn through the rollers ensuring complete saturation of the liner material layers. As the liner comes off the bed it is submerged into an ice bath to slow down the curing of the resin. The liner is then pulled into the refrigerated vehicle with ice being introduced between each stacked layer. The refrigerated vehicle is then driven to site.

Onsite chose an air inversion with a steam cure method for installation, as this was a much easier and cost effective way of installing the liner.

For this method, the liner is inverted through the host pipe and steam is introduced at the steam generation station, and the resin in the liner starts curing with the steam at temperatures of up to 100°Celsius.

After holding this for four hours, the liner is allowed to cool and end sealing mechanisms are installed.

The enabling works, liner impregnation, delivery and installation of five individual liners was completed in three weeks and the pipeline was put back into service a few weeks later.